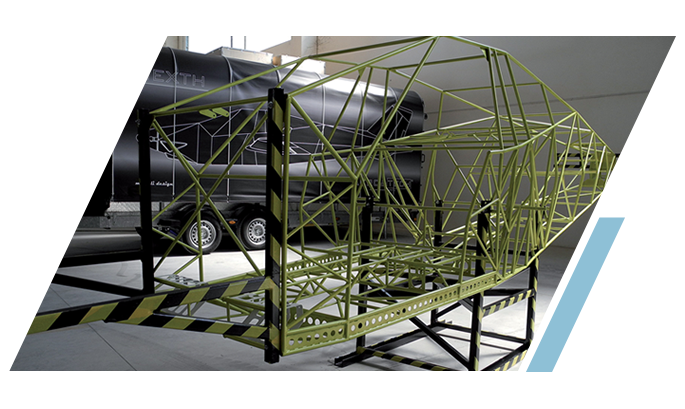

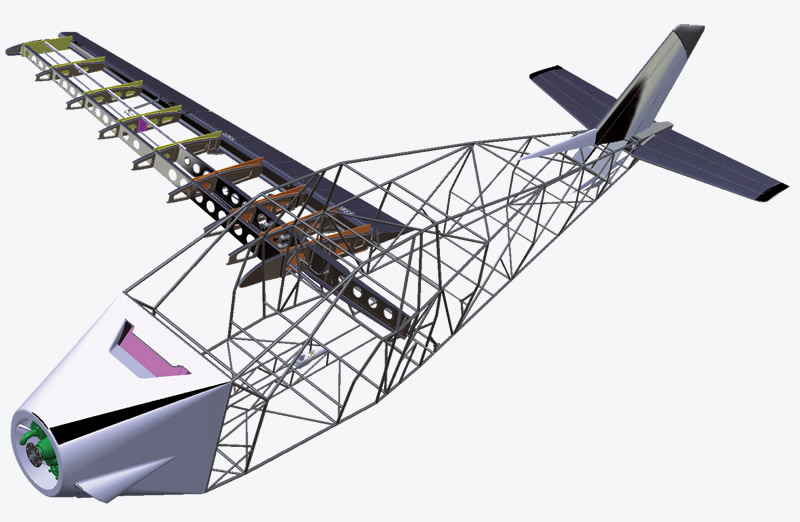

As in Formula 1 AERO&TECH improved the same technologies of materials and production processes, in order to reach less weight, that means more safety with shorter takeoff lengths and better climb ratio to reach a safe altitude faster and with safety. NEXTH has reached the important result of an empty weight of 298.5 kg within ultimate load factors tested at +9G and -4.5 G; a success with difficult compare.

Discover NEXTH

Formula 1 Technology & Aerobatic Strenght

Nexth if you want to enjoy with no worries your flight also with turbulences and to protect you and your passenger.

NEXT-H... ACRO Strenght & your first Safety Cell

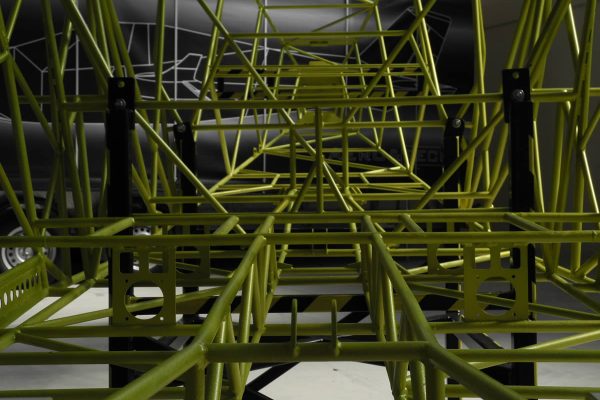

AERO&TECH is the first company to introduce the special high-performance steel tubes from Formula 1 and long used successfully by the most prestigious sports cars for the exceptional technical characteristics and higher strength, thanks to the 15CDV6 strength RM of 1280 N/mm2 against the normal max RM 600/800 value of common 4130 tubes.AERO&TECH has developed with its internal R&S department a dedicated producing process based on the following features:

- Protective welding atmosphere and internal protective anti-corrosion treatment heat treatment of the welded nodes with a 15% increasing strength

- Fuselage and engine mount frame with pressured test indicators for constant control inspections

- No destructive weld resistance tests with x-ray and penetrating liquids

for an all enveloping closed safety cell designed to absorb with elastic deformation the impact energy.

ACRO +9 - 4.5 - 298.5 kg

Numbers and facts, not words

A responsible project manager choice with +9G – 4.5 G ultimate load factors, among the highest in the ultralight category, combined with the docility of a simple, easy and safe aircraft. Aerobatic to invest in safe solidity, not for aerobacy, however forbidden, but to have safety in turbulence or emergency, to protect your person and who shares the flight with you, to have a stronger aircraft…. added value that not allows doubts in the choice of Nexth.

The wide application of the most advanced material technology and work processes as:

- Full machined aluminum components with certified ultrasonic tested 7075 T6 and titanium GR5

- Autoclave high pressure procedure for carbon components (however never used for no structural elements)

in order to improve strength/weight ratio and safety, permits NEXTH to maintain the minimum empty weight under 300 kg, as required by LTF-UL rules, and to reach a so high strength permitting tow activities up to 1000 kg.